Online Watch

Showing posts with label QUALITY MANUAL. Show all posts

Showing posts with label QUALITY MANUAL. Show all posts

Monday, August 22, 2016

QUALITY POLICY AND OBJECTIVE

Labels:

QUALITY MANUAL

BANGLADESH

Bangladesh

QUALITY ASSURANCE MANUAL

NOTE 1: This is a CONTROLLED Document as are all quality system files on this server. Any documents appearing in paper form are not controlled and should be checked against the server file version prior to use.

NOTE 2: The document below is a high level sample. For a comprehensive MS-Word based template, we would suggest the one included within the ISO 9000 Management Kit (commercial site).

Section Title | Related Procedure | |

| 1. | Introduction & Company Profile | |

| 2. | Policy & Objectives | |

| 3. | Definitions | |

| 4. | Quality System | |

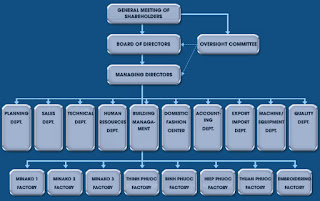

| 5. | Organization | Organization Chart |

| 6. | Authority & Responsibilities | |

| 7. | Compliance to ISO9001 | |

| 8. | Management Review & Internal Audit | Management Review |

| Internal Audit | ||

| 9. | Contract Review | Product Sales |

| 10. | Design | System Design |

| 11. | Documentation & Change Control | External Documents |

| Quality System Documentation | ||

| 12. | Purchasing | Purchasing |

| 13. | Customer Supplied Items | |

| 14. | Process Control | Product Installations |

| Maintenance | ||

| 15. | Receiving Inspection | Receiving Inspection |

| 16. | Inspection & Testing | |

| 17. | Production & Measuring Equipment | |

| 18. | Indication of Inspection Status | Installation |

| Material Control | ||

| Maintenance | ||

| 19. | Non-conforming Items, Preventive & Corrective Action | |

| 20. | Handling, Storage, Packaging, Preservation & Delivery | |

| 21. | Records | |

| 22. | Training | Training |

| 23. | Servicing | Maintenance |

1.0 INTRODUCTION

Additional capabilities have been added to the organization to include technical assistance and support, installation, maintenance of products and systems, and design of systems.

The company is now engaged in including design, engineering, stocking and distribution, installation, commissioning and maintenance of equipment and systems.

This Quality System relates to the full range of company activities.

2.0 POLICY and OBJECTIVES

This level of quality is achieved through adoption of a system of procedures that reflect the competence of the Company to existing customers, potential customers, and independent auditing authorities.

Achievement of this policy involves all staff, who are individually responsible for the quality of their work, resulting in a continually improving working environment for all. This policy is provided and explained to each employee by the Managing Director or Quality Manager.

To achieve and maintain the required level of assurance the Managing Director retains responsibility for the Quality System with routine operation controlled by the Quality Manager.

The objectives of the Quality Assurance System are:

a) To maintain an effective Quality Assurance System complying with International Standard ISO9001 (Quality Systems).

b) To achieve and maintain a level of quality which enhances the Company's reputation with customers.

c) To ensure compliance with relevant statutory and safety requirements.

d) To endeavor, at all times, to maximize customer satisfaction with the services provided by Net Work Systems

H Bridge - Managing Director

October 1995

3.0 DEFINITIONS

Additional definitions apply for items not covered by the documents:

Site Any location, other than the Company's established premises, where work is undertaken as part of a formal contract

4.0 QUALITY SYSTEM

Level 1 : Quality Manual

This document details the corporate quality policy and structure of the Company and references appropriate Operating Procedures.

Level 2 : Operating Procedures

These documents describe the actual process, and controls applied, to all activities concerned with the attainment of a quality assured contracting service.

A list of Operating Procedures is given in the Index Section of this Quality Assurance Manual.

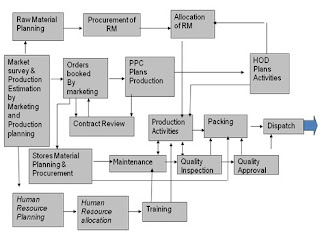

Quality Planning

As the Company operates a standard type and range of services, customer satisfaction and quality are achieved by operation in accordance with the documented quality system. Specific customer requirements are identified and documented during the contract review process, allowing these requirements to be communicated and achieved, ensuring satisfaction of all customer declared needs.

5.0 Organization

This will only work if your browser supports Client-Side Image Maps

If not, move down to the text descriptions

6.0 AUTHORITY & RESPONSIBILITIES

6.1 Authority

6.1.1 All staff are allocated with authority to perform their allocated responsibilities. The following provides a summary of the principal responsibilities of each job role, and these are clarified in greater detail within the Operating Procedures.6.1.2 All staff share the authority and responsibility of identifying noncompliances or possible improvements, and recording these instances such that corrective action can be taken, both to rectify the immediate situation and to prevent recurrence.

6.1.3 The Managing Director continually reviews the company's resources to ensure that adequate staff, equipment and materials are available to meet customer requirements.

6.2 Responsibilities

6.2.1 Managing Director- Approval of the Quality Assurance System

- Management Review

- Design Control

- Supplier Selection & Purchasing

- Contract Management & Control

- Training

- Internal Audit

- Resolution of Quality Assurance System Discrepancies

- Control & Maintenance of the Quality Assurance System

- Documentation & Change Control (Quality System Documents)

- Management & Co-ordination of Sales and Support Functions

- Contract Review

- Sales Order Processing

- Design Control

- Estimating

- Project Management

- Control of Contract Documentation

- Planning & organization

- Supplier Selection & Purchasing

- Definition of Installation, Inspection, Test & Maintenance Requirements

- Training

- Quotations

- Contract Review and Order Processing

- Planning and Co-ordination

- Control of Production and Measuring Equipment

- Maintenance of Support Stores

- Processing of Sales Orders

- Purchasing

- Planning & Performance of Installation, Technical Assistance,

- Repairs, Testing and Maintenance Activities

- Control of Equipment and Materials Allocated

- Control of Finance, Accounts and Warehouse Operations

- Training

- Supplier Selection and Purchasing

- Control of Stock

- Replenishment Recommendation

- Protection and Preservation of Stock

- Receiving Inspection

- Packaging and Despatch

- Sales

- Estimating

- New Product Identification & Evaluation

- System Design

- Sales Database Administration

- Checking of Sales Orders

- Allocation of Order Reference Numbers

7. COMPLIANCE WITH ISO9001

- Statistical Techniques

8. MANAGEMENT REVIEW and INTERNAL AUDIT

The objectives of Management Review are:

a) To establish that the Quality (Management) System is achieving the expected results and meeting the Company's requirements, continuing to conform to the Standard, continuing to satisfy the customers needs and expectations, and functioning in accordance with the established Operating Procedures.

b) To expose irregularities or defects in the System, identify weaknesses and evaluate possible improvements.

c) To review the effectiveness of previous corrective actions, and to review the adequacy and suitability of the management system for current and future operations of the Company.

d) To review any complaints received, identify the cause and recommend corrective action if required.

e) To review the finding of internal/ external audits and identify any areas of recurring problems or potential improvements.

f) To review the reports of nonconforming items and trend information to identify possible improvements.

Internal audits of the Quality System are undertaken at least once per annum to confirm that the function concerned is adhering to the Company's Procedures. A comprehensive Audit Programme is compiled at least a year in advance however, should particular needs be identified, the frequency of audit may be increased at the discretion of the Quality Manager.

Audits are undertaken by auditors who are trained in auditing and not directly responsible for the functions being audited within that Company. Nonconformance observed is brought to the attention of the person responsible, and is recorded, documented and subject to timely corrective action to ensure full rectification.

9. CONTRACT REVIEW

Once a proposal is accepted by the customer, or an order is placed, it is recorded and reviewed to establish that the requirements of the order are adequately defined and documented, any differences from the proposal are resolved, and the Company is capable of fully satisfying the customers requirements.

In addition to the original order/ contract specification the customer may also request addition/ variation work to be undertaken by the Company. In these circumstances the work content is documented and agreed with the customer prior to execution to ensure that no ambiguity exists.

The Company operates on a computerized order processing system to ensure rapid fulfillment of customer orders.

10. DESIGN CONTROL

Design activities are planned and normally executed by specialists and are subject to regular management, review and verification by the Sales Director, and where relevant, agreement with the Customer.

The design input and output items are documented, and where ambiguity exists, will be clarified and documented. All items of design documentation and notes are recorded in a design project file. Design output documentation is produced and reviewed to ensure that it:

- meets the design input,

- references the design input or appropriate criteria,

- and identifies all of the characteristics which are critical to the safe and effective operation of the system(s).

The designer is required to specify any inspections or tests which may verify the design, by practical means, at the earliest possible stage of development.

All changes to the design criteria, input or output are subject to strict review and documentation control procedures.

11. DOCUMENTATION & CHANGE CONTROL

Such documentation typically includes:

Quality Assurance Manual/ Operating Procedures,

National/ International Standards and Codes of Practice.

National/ International Standards, Codes of Practice are maintained by the Support Engineers who ensure that appropriate documents are available within the Company, and are issued at the correct revision levels. External suppliers of documentation are contacted regularly to ascertain that the documents held remain current.

The distribution of standard documents is controlled and recorded on Distribution Lists, which also show the current issue status. The Distribution Lists are reviewed and updated as changes occur.

All changes to documents are reviewed and approved by the person responsible for the original issue and, where appropriate, the nature of the change is indicated on the document. Master copies of the revised documents are retained as records of the changes and renewed as necessary to ensure clarity.

Each contract has a File which contains all relevant information. Information is also held on the company's computer system for ease of access and manipulation.

12. PURCHASING

a) Previous performance in supplying to similar specifications and requirements.

b) Stocking of high volume standard items conforming to a relevant British Standard, or supplied with a statement of conformity.

c) Compliance with an approved third party product/ quality registration scheme.

d) Recommendation by other similar purchasers or manufacturers of equipment.

e) A trial order and evaluation of performance.

All supplies and sub-contracts are subject to an authorized Purchase Order providing full clarification of the type and extent of supply.

Should a supplier, not appearing on the Approved Suppliers List be proposed, they will be analysed by capability and subject to acceptance on the authority of a Director.

13. CUSTOMER SUPPLIED ITEMS

14. PROCESS CONTROL

Work instructions are provided by the agreed contract specification and any documents referenced therein, alternatively work is performed in accordance with nationally accepted codes of practice (e.g. BS6701).

15. RECEIVING INSPECTION

All goods received are documented and, in the event of non-conformance, the items are placed in a reject area or labelled to ensure identification. The extent of the non-conformance is noted and subject to disposition review by nominated personnel.

16. INSPECTION AND TESTING

On completion of installation and maintenance works, the customer is also invited to check the work performed to ensure full acceptability.

17. PRODUCTION & MEASURING EQUIPMENT

Electrostatic protection equipment is utilized when handling sensitive components, and this equipment is regularly checked to ensure that it remains fully functional.

18. INDICATION OF INSPECTION STATUS

19. NON-CONFORMING ITEMS, PREVENTIVE & CORRECTIVE ACTION

The corrective action required to prevent recurrence is evaluated, documented, and its effective implementation is monitored. All rectification is subsequently re-inspected to ensure complete customer satisfaction.

All employees are encouraged to suggest improvements in methods, materials, suppliers,

and sub-contractors. The Company has established procedures for review of all activities in order to identify and evaluate all possible improvements in methods/ materials and its procedures.

20. HANDLING, STORAGE, PACKAGING, PRESERVATION & DELIVERY

All items with serial numbers are recorded individually.

Materials and goods received, whether the property of the company or others, will, as far as practicable, be protected and their quality preserved until such time as they are transferred to a customer, or disposed of to a third party. The objective is to prevent deterioration and damage whilst in storage, or in the process of transportation, installation, commissioning or maintenance.

21. RECORDS

Where records are maintained on computer magnetic media, and these are subject to "back-up" at regular intervals, with the "back-up" information being stored in a protected location to ensure security from loss/ damage of active data.

All records are retained for a minimum of 2 years.

22. TRAINING

All staff and senior employees are responsible for recommending the training needs of others, and for ensuring that all employees allocated specific tasks are suitably qualified and experienced to execute those tasks. Once training needs are identified these are provided under the responsibility of the Directors.

Full records are maintained of all training undertaken by employees.

23. SERVICING

Labels:

QUALITY MANUAL

BANGLADESH

Bangladesh

Subscribe to:

Comments (Atom)