Online Watch

Thursday, May 12, 2016

Sunday, May 08, 2016

Quality Training Content:

|

1.

Garments Checking System.

|

2.

Shade Band.

|

|

3.

Sewing Defect Identification.

|

4.

Shrinkage Test.

|

|

5.

Measurement.

|

6.

Color Rubbing Test.

|

|

7.

Garments Appearance.

|

8.

Barcode Sticker.

|

|

9.

Shade Verification.

|

10.

Needle Management.

|

|

11.

Hole/Button/Bar tack/Eyelet/Rivet/Stud/Sequence.

|

12.

Accessories.

|

|

13.

Fabric Defect.

|

14.

Sewing IPC.

|

|

15.

Shape Symmetrical.

|

16.

Finishing IPC.

|

|

17.

Stepping/Roping/ Pulling/ shearing/Puckering/Weaving.

|

18.

Hourly Audit.

|

|

19.

Traffic Light System.

|

20.

Pre-Final.

|

|

21.

First Production of Sample Review.

|

22.

Package Check.

|

|

23.

Pilot- run/ Test-cut Procedure.

|

24.

Ratio.

|

|

25.

Bundle Standard System.

|

26.

Packing.

|

|

27.

Mock up.

|

28.

Carton Test.

|

|

29.

Double Pocket/ Double Flap/ Deco stitch.

|

30.

Metal Check.

|

|

31.

Fusing.

|

32.

Ferrous test

|

|

33.

Interlining.

|

34.

Bond test

|

|

35.

Button Pull Test.

|

36.

Moisture test

|

|

37.

Lining Test.

|

38.

Nickel test.

|

|

39.

Fabric Inspection.

|

40.

Button pull test.

|

Labels:

QUALITY

BANGLADESH

Bangladesh

Quality Training Content :

1. Garments checking System.

2. Sewing Defect identification.

3. Measurement.

4. Garments Appearance.

5. Shading & Verification.

6. Hole/Button/bar tack/Eyelet/Rivet/stud/sequence.

7. Fabric Defect.

8. Shape symmetrical.

9. Stepping/Roping/ pullness/ shearing/pucaring/ Weaving/

10. Traffic light System.

11. First production sample Review.

12. Pilot- run/ Test-cut procedure.

13. Bundle standard system.

14. Mock up.

15. Double Pocket/ Double Flap/ Deco stitch.

16. Fusing.

17. Inter lining.

18. Button pull test.

19. Lining test.

20. Fabric inspection.

21. Shade band.

22. Shrinkage test.

23. Color rubbing test.

24. Barcode sticker.

25. Needle.

26. Accessories.

27. Sewing IPC.

28. Finishing IPC

29. Hourly audit

30. Pre-Final

31. Package check.

32. Ratio

33. Packing.

34. Carton.

Labels:

QUALITY

BANGLADESH

Bangladesh

Wednesday, May 04, 2016

Garments Pattern Making step by step

Patterns are paper templates for all the components of a garment,

such as cloths, lining, interlining which have to be cut for a

garments. These patterns are used to draw sketch on cloth or marker

paper.

Steps of pattern making:

Patterns are made in two steps:

Steps of pattern making:

Patterns are made in two steps:

- Block pattern.

- Working pattern.

Block pattern or basic block indicates

the original pattern. Block Pattern is made based on the specific and

standard body measurement without any design or style. It is produced

according to exact dimension of body for different age group and gender.

Block pattern making method:

i. Flat method: In this method, different parts of garments, specially major parts are made by technical drawing. In the technical drawing, proportion of different parts of a garment is considered. This pattern can be made by both manual and computerized method.

ii. Modeling: It is primary and first method and widely used in garment industry. Block is made with standard body measurement of mannequin. This block is called toile. Toile is worn on the mannequin and adjusted the pattern necessarily. Then Toile is worn out from the body and individual parts of Toile are drawn on hard paper.

2. Working pattern:

Block pattern making method:

i. Flat method: In this method, different parts of garments, specially major parts are made by technical drawing. In the technical drawing, proportion of different parts of a garment is considered. This pattern can be made by both manual and computerized method.

ii. Modeling: It is primary and first method and widely used in garment industry. Block is made with standard body measurement of mannequin. This block is called toile. Toile is worn on the mannequin and adjusted the pattern necessarily. Then Toile is worn out from the body and individual parts of Toile are drawn on hard paper.

|

| Manual pattern making |

Working pattern is derived from the flat

method or modeling. Each and every pattern is laid on the board paper

to copy the block pattern. Then sewing allowance, Trimming allowance,

Button hole, button attaching, dart, pleat, Notch, shrinkage of the

fabric, etc are added with the copied pattern. Working pattern are

needed for each an every part of the garments.

Grading:

Grading means the step wise increase or decrease of a master pattern piece to create larger or smaller sizes. The starting point can be the smallest size or the middle size. Grading alters the overall size of a design but not its general shape

Two methods of Grading:

The desired range of sizes is created one by one using a pattern template. Marks are made around the master pattern at the appropriate distance and the marks are later joined up to form the enlarged pattern. In this way a full set of templates, the pattern set is generated.

A Grading machine eases the task of creating the pattern set. The device grips the master pattern and displaces it by a precise vertical and horizontal distance, after which the appropriate edge can be traced.

Computer aided Grading:

Computer based Grading systems are operating in one of two ways:

A.

Some important definition related to pattern making:

Darts: The purpose of dart is to eliminate excessive fabric in a pattern so that it can conform into the shape of a human body.

Grain Line: Pattern pieces normally carry a line is called Grain line. Grain Line of pattern pieces usually is parallel to the warp (woven) or wale (knit). The actual direction depends on whether the pattern is to align with the warp, weft, wale or course when laid on the . The direction of the grain line is therefore determined by the designer.

Drill Holes: Drill holes are small holes drilled into pattern to indicate where other components (such as pockets) should be superimposed.

Grading:

Grading means the step wise increase or decrease of a master pattern piece to create larger or smaller sizes. The starting point can be the smallest size or the middle size. Grading alters the overall size of a design but not its general shape

Two methods of Grading:

- Manual Grading

- Computer aided Grading

The desired range of sizes is created one by one using a pattern template. Marks are made around the master pattern at the appropriate distance and the marks are later joined up to form the enlarged pattern. In this way a full set of templates, the pattern set is generated.

A Grading machine eases the task of creating the pattern set. The device grips the master pattern and displaces it by a precise vertical and horizontal distance, after which the appropriate edge can be traced.

Computer aided Grading:

Computer based Grading systems are operating in one of two ways:

A.

- The patterns can be cut out and can be used to make marker manually, if necessary.

- The graded sizes can be stored in the model files of the computer and recalled when cutting markers for that style are to be planned on the system.

- The grading increments are fed in to the computer and the different sizes are generated automatically using the same method as applied for manual Grading.

- The pattern for each individual size is calculated separately starting from the data in the size charts. The resulting layer of the patterns can be displayed to scale on the computer monitor for visual assessment and if necessary adjustment.

Some important definition related to pattern making:

Darts: The purpose of dart is to eliminate excessive fabric in a pattern so that it can conform into the shape of a human body.

Grain Line: Pattern pieces normally carry a line is called Grain line. Grain Line of pattern pieces usually is parallel to the warp (woven) or wale (knit). The actual direction depends on whether the pattern is to align with the warp, weft, wale or course when laid on the . The direction of the grain line is therefore determined by the designer.

Drill Holes: Drill holes are small holes drilled into pattern to indicate where other components (such as pockets) should be superimposed.

Labels:

PATTERN

BANGLADESH

Bangladesh

Tuesday, May 03, 2016

SOP For managers/ Responsibility of Manager

একটি সম্প্রুন ইউনিট এর কোয়ালিটি ইন-চাজ হিসাবে

নিম্নোলিখিত দায়ীত্তো কতব্য পালন করতে হবে।দায়ীত্তো কতব্য সমুহ নিম্নে ধারাবাহীক ভাবে বর্ণনা করা হল।

*১।রিপরটিং করার নিয়মাবলীঃ

প্রতিদিন সকাল নয়টার মধ্যে নিজ ইউনিট এর কোয়ালিটি স্টাটাস ম্যানেজারকে জানাতে

হবে।

(ক). রানিং স্টাইল সমুহ।

(খ). প্রডাক্সন স্টাটাস।

(গ). প্রত্যেক লাইনের

ডি.এইস.ইউ ও ডিফেক্টিভ পারসেন্টেজ।

(ঘ). বাইয়ার ইন-লাইন ও

ফাইনাল রিপোট।

(ঙ). কিউ,এ আউয়ারলি

রিপটের সামারি।

(চ). পি,পি মিটিং এর বিষয়

উইথ পি,পি রেজিস্টার।

(ছ). স্পেসাল কমেন্টস।

(জ). ম্যান পাওয়ার কন্ত্রোল।

(ঝ). ডেইলি প্লান।

(ঞ). নতুন স্টাইল এর

স্টাইল এ্যপ্রুভ করাতে হবে।

*২। ইউনিট পরিচালনাঃ

(ক).প্রত্যেক সুপারভাইসর কে তার

নিজ নিজ কাজ বুঝিয়ে দিতে হবে এবং সফল ভাবে কাজ বুঝে নিতে হবে।

(খ). নিজ ইউনিটের সকল সেকসনের

সফলতা ও ব্যথতার সমস্ত দায়ভার নিজেকে গ্রহন করতে হবে।

(গ). নিজ ইউনিটের সকল সেকসনের

(কাটিং,সুইং এবং ফিনিসিং )যাবতীয় ডিসিশন নিজে প্রদান করতে হবে।

*৩। সাপ্তাহিক মিটিংঃ

(ক).প্রতি সপ্তাহের মিটিং এর দিনে

সাপ্তাহিক প্লান জানাতে হবে।

# সপ্তাহের রানিং বায়ার।

# সপ্তাহের টোটাল অডার

কোয়ান্টিটি।

# পি.পি মিটিং।

#

ইনস্পেকশন ডেট।

# বায়ার ইনেস্পেকটর মোটিভেসন

প্লান।

# সাপ্তাহিক ডিফেক্ট রিডুইসিং।

# ইন্সপেকশন ফেল হলে তার রুট কজ

এনালালাইসিস।

Labels:

Q.C MANAGER SOP

BANGLADESH

Bangladesh

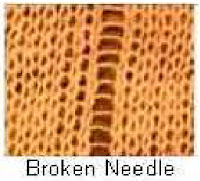

Some fabric defects Name with picture

Labels:

Fabric Defects

BANGLADESH

Bangladesh

DEFECTS LIST AND CATEGORY OF TRIMS AND ACCESSORIES

Critical

Defects:

1. Wrong

Country Name

2. Wrong Buyer

Name

3. Wrong

Barcode Number

4. Wrong RN

Number

5. Wrong CA

Number

6. Wrong Size

Number

7. Wrong Care

Instruction

8. Wrong

Composition

Major

Defects:

1. Printing

Problem

2.

Broken Teeth

3.

Broken Puller

4.

Stopper Problem

5.

Broken Button

6.

Button Dice problem

7.

Cutting Problem

8.

Weaving Problem

9.

Foreign Yarn Problem

10.

Slub Yarn Problem

Minor Defects:

1. Spot Problem

2. Shade Variation

Subscribe to:

Comments (Atom)